OUR PLATFORM

Discover all your knowledge can do

Start with the software that brings digital chemistry, manufacturing, and controls (CMC) to pharma and biotech for the first time.

Digital CMC for drug products

In an industry full of retrofit software solutions, QbDVision is a purebred platform for pharma and biotech – – purpose-built to deliver the solutions that matter most for teams like yours.

your unstructured knowledge and data

repetitive tasks and complex workflows

across teams and functions

exactly how your projects and risks are evolving

your data and ensure it’s regulator-ready

development of new breakthrough therapies

OUR FOCUS

Solving a legacy challenge

Today, lack of structure slows development

Our industry still leaves its knowledge and data scattered across inboxes, folders, spreadsheets, PDFs, and legacy QMS. The result: inefficient processes, poor process understanding, product quality risks, and product life cycles delayed by information barriers.

Our structured platform brings it all together

QbDVision provides a unified framework that connects it all — your information, your processes, and your people — in ways that help teams turn science into products with unprecedented efficiency, coordination, and agility.

WHAT YOU GET

One software with all the tools you need

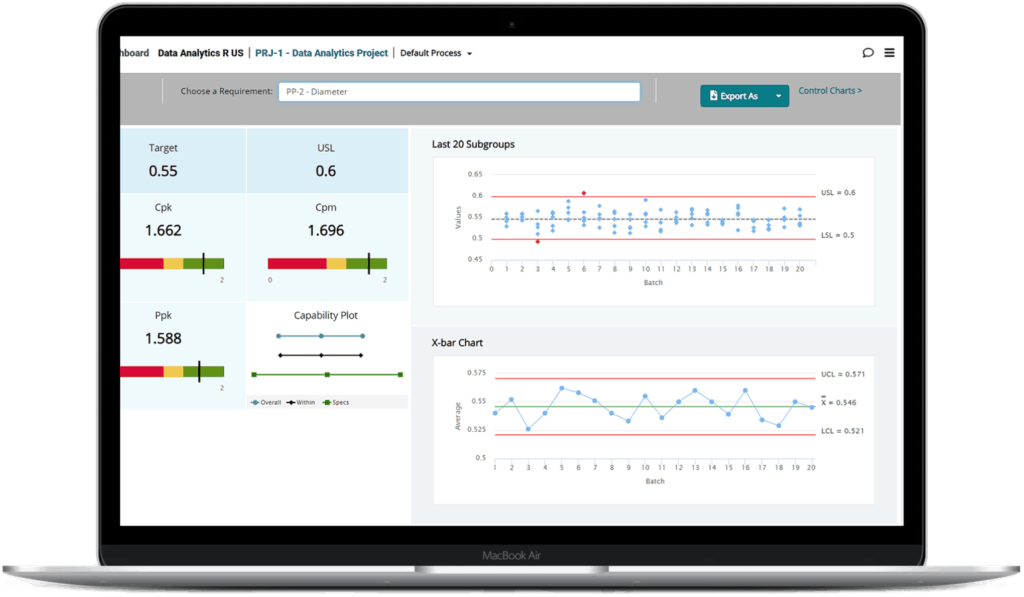

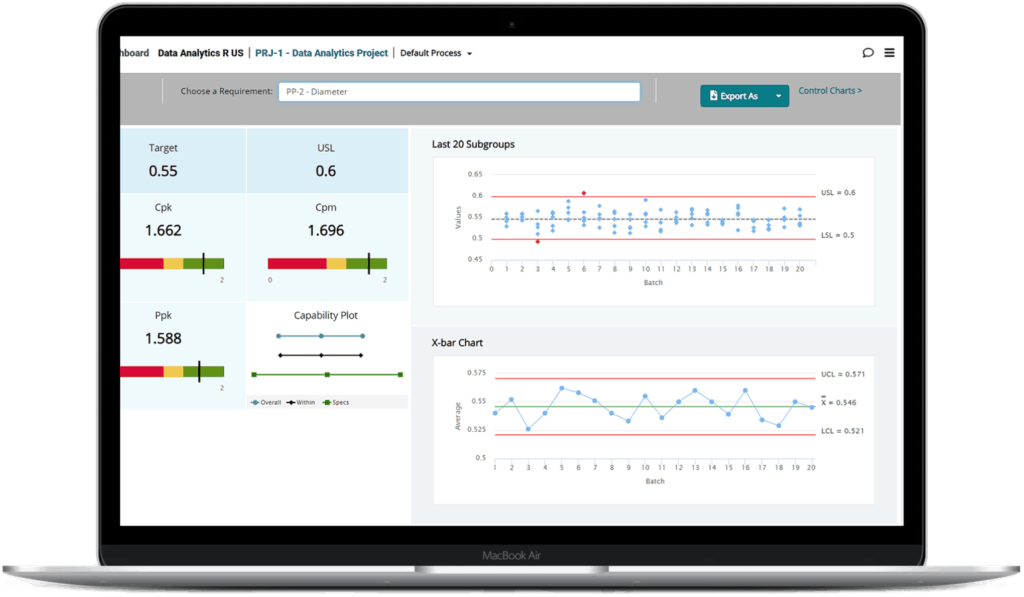

With QbDVision, they can manage everything from a single login — process evolution, risk evaluation, and data analytics — without the inefficiency and data integrity risks of disconnected, legacy software solutions that create barriers to shared knowledge.

WHAT YOU GET

One software with all the tools you need

With QbDVision, they can manage everything from a single login — process evolution, risk evaluation, and data analytics — without the inefficiency and data integrity risks of disconnected, legacy software solutions that create barriers to shared knowledge.

WHAT QbDVISION CREATES

A foundation for simpler workflows and smarter decisions

With all your knowledge, data, and systems in one place, you can finally sync up all the workflows that depend on those resources. And with all those activities in sync, it’s easy to see how you can optimize every one of them.

Solve fragmentation

Unite siloed workflows, reveal implicit knowledge, and collect scattered data.

Consolidate information

Create a shared, centralized knowledge base with a structured framework.

Enhance coordination

Make it easy for your teams to work together, align approaches, and transfer knowledge.

Create intelligence

Make every decision based on contextual guidance and visualized insights.

WHAT IT DELIVERS

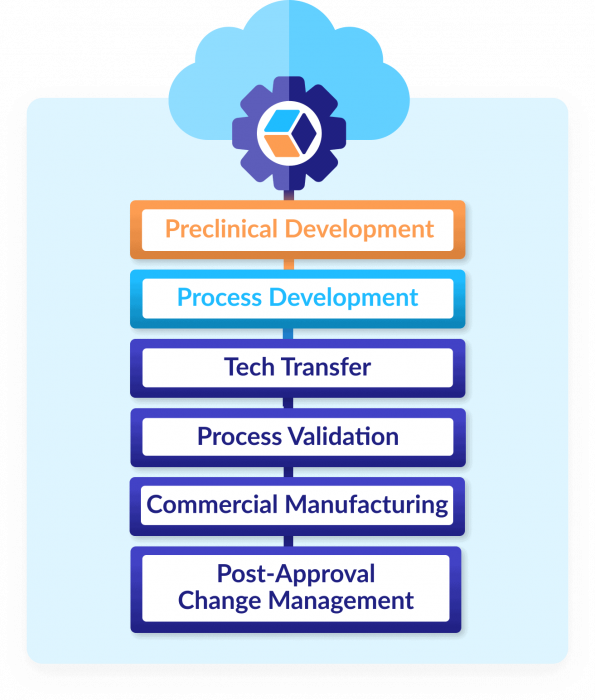

A modern digital path to efficient, agile CMC

As your product and processes evolve in QbDVision, so do your understanding and control. Using our platform ensures you always have a holistic, historical view of the entire life cycle — so you can always make the best decision at exactly the right time.

KEY FEATURES

Benefits of a structured platform

Fast deployment

Your teams can be up and running on our cloud-based software in minutes. With our intuitive user interfaces, inline documentation, and world-class customer support, your teams can bring down data silos and start building a shared knowledge base in a few clicks.

Built-in compliance

Every click in QbDVision facilitates compliance with ICH and ISO quality guidelines, 21 CFR 11, and EU Annex 11 data integrity requirements. Users and regulators can easily access the complete, accurate, and fully contextualized information they need at every step of the product life cycle.

Robust security

GO DEEPER

See everything our platform makes possible

KNOW WHERE

Centralized knowledge management

Collect all your teams’ data and knowledge in one searchable, cloud-based hub.

KNOW HOW

Streamlined process development

Create robust, agile processes that your teams can control as one.

KNOW WHY

Powerful process intelligence

See what every action means for the whole product life cycle.