KNOW WHERE

Centralize your data and knowledge

Consolidate and integrate all your teams’ development resources on a single, searchable platform.

Everything your teams know, all in one place

Drug development processes create astounding amounts of information. But insights? All too often, they stay hidden in static documents or siloed knowledge bases.

Now you can finally consolidate your teams’ wealth of dispersed data and knowledge. And discover what it can really be worth.

CONSOLIDATE

Create a single, structured source of truth

Give your teams one destination for all the information they need to advance your product’s development, including:

- Patient, product, and process requirements

- Acceptance criteria

- Notes, sketches, and diagrams

- Reports & updates

- Transfer information

CONSOLIDATE

Create a single, structured source of truth

Give your teams one destination for all the information they need to advance your product’s development, including:

- Patient, product, and process requirements

- Acceptance criteria

- Notes, sketches, and diagrams

- Reports & updates

- Transfer information

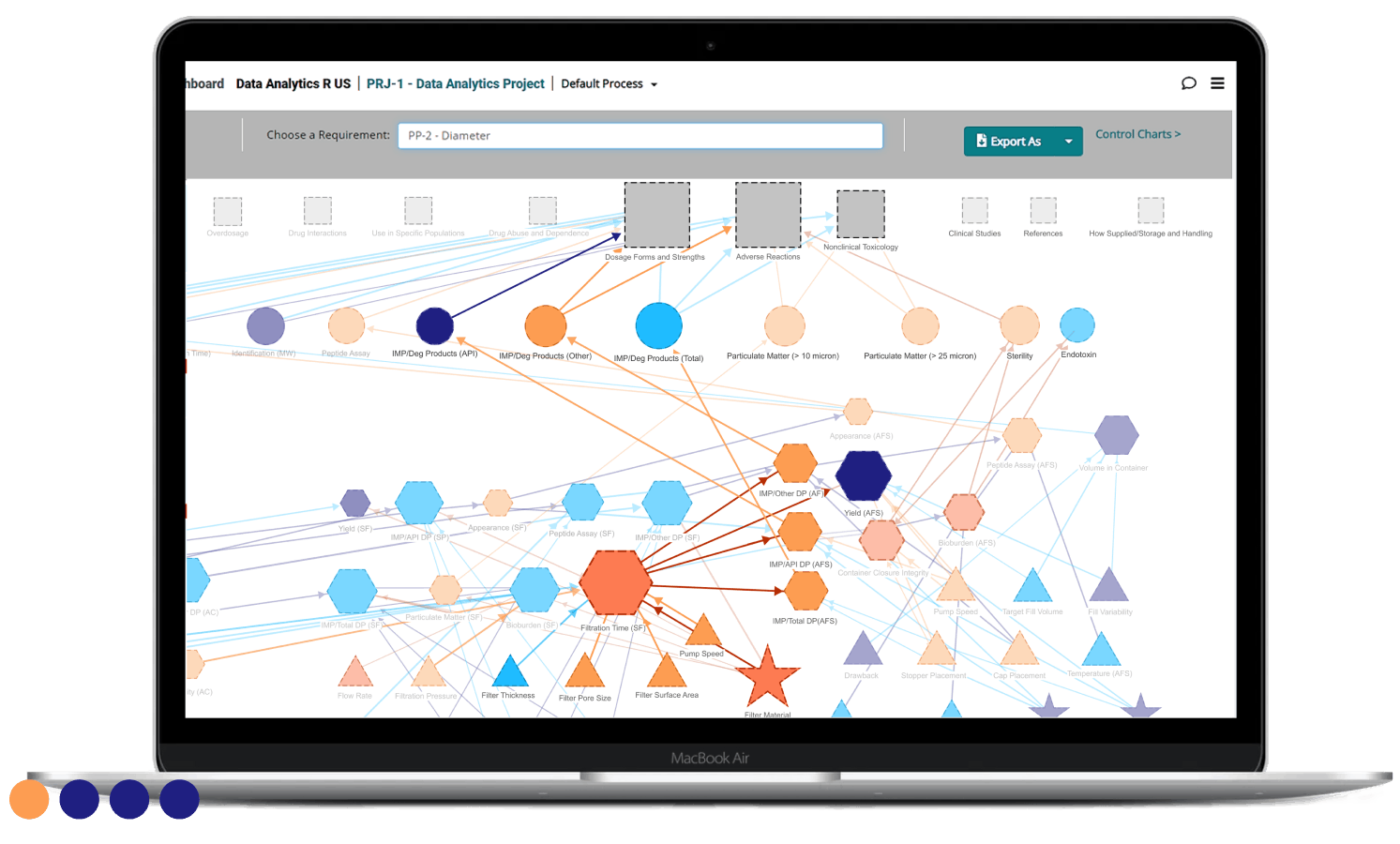

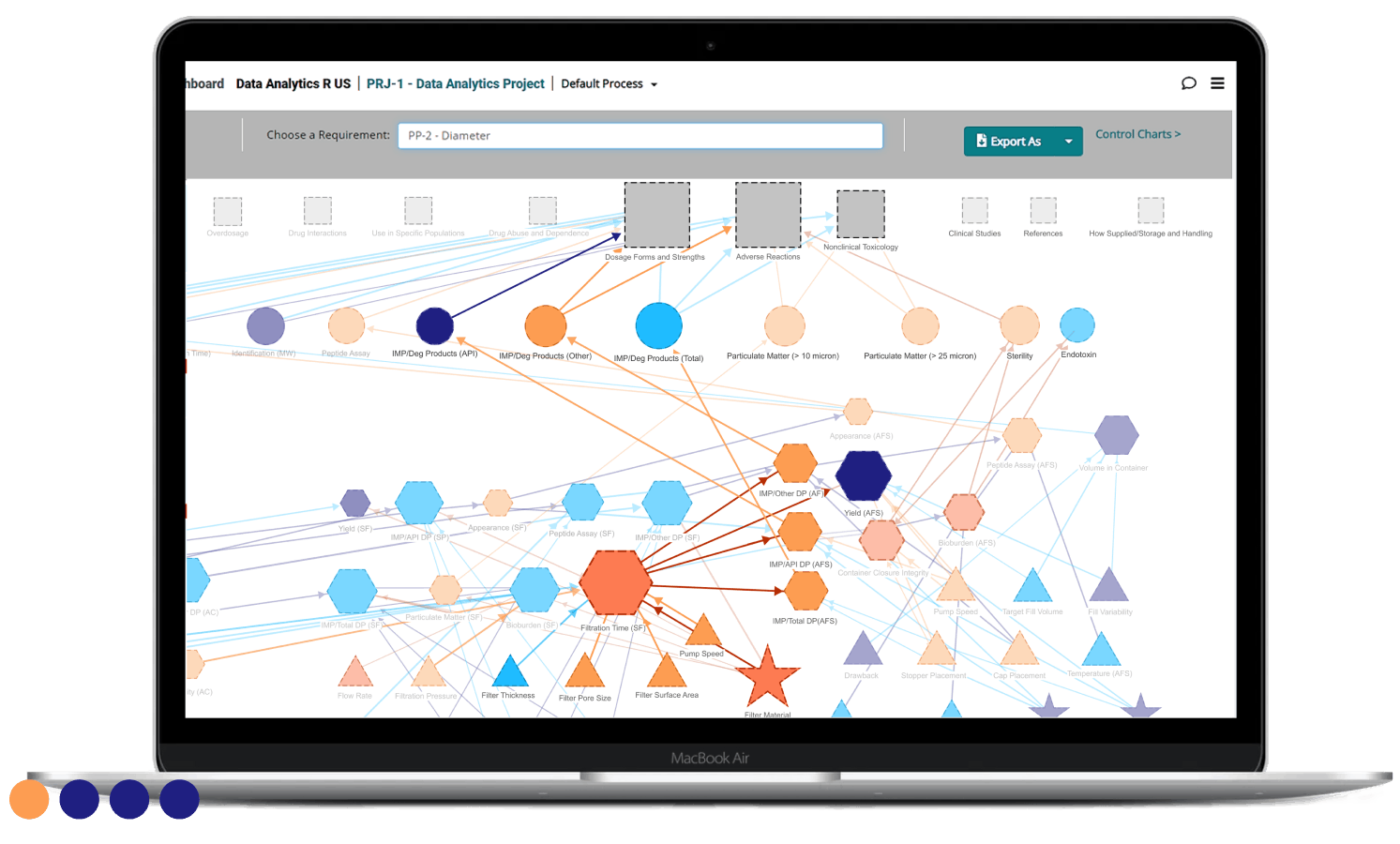

CONNECT

Manage it all right here

All your teams can finally create, sync, and share their critical project information with one software. QbDVision syncs all their knowledge and data across functions, workflows, and materials, from process, to product, to patient.

UNIFY

Bring everyone together on one platform

Drug development teams are more dispersed than ever. QbDVision gives them a dedicated space to share information, resources, and visibility into each other’s workflows. If it can help them make smarter decisions, avoid redundancies, or better understand their evolving processes, they can find it here.

UNIFY

Bring everyone together on one platform

Drug development teams are more dispersed than ever. QbDVision gives them a dedicated space to share information, resources, and visibility into each other’s workflows. If it can help them make smarter decisions, avoid redundancies, or better understand their evolving processes, they can find it here.

STREAMLINE

Move to an automation-ready framework

Lay the groundwork for automating complex, time-intensive activities. Users can easily create standardized workflows that streamline compliance with industry guidelines and best practices — including analytics, reporting, risk assessments, and more.

FEATURED SOLUTION

Run critical reports with a click

Forget wasting hours writing and updating reports. QbDVision provides the clean, structured data you need to complete this multiweek manual task in minutes.

- Generate and update reports in real time

- Instantly create visualized dashboards

- Create historical lookbacks at any time

GO DEEPER

See everything our platform makes possible

OUR PRODUCT

Modern software for pharma and biotech

See how QbDVision digitizes management of the whole product life cycle.

KNOW HOW

Streamlined process development

Create robust, agile processes that your teams can control as one.

KNOW WHY

Powerful process intelligence

See what every action means for the whole product life cycle.

See it all come together

Find out how easy it is to consolidate all your data and knowledge in one modern digital platform.